If your tubewell water turns reddish, stains tiles, smells metallic, or blocks pipes, you need an Iron Removal Plant (IRP). It is a water treatment plant that oxidizes dissolved iron and then filters it out so your water looks clear, tastes better, and is safer for your plumbing and equipment.

CleanTech Engineering LTD designs and supplies domestic, apartment, commercial, and industrial iron removal plants in Bangladesh based on your water test and required flow rate (LPH).

What Is an Iron Removal Plant

An Iron Removal Plant is a water purification system that removes dissolved iron from groundwater by turning it into solid particles and filtering it.

Tubewell groundwater often contains dissolved iron (Fe²⁺) that you cannot see when the water comes out. After a few minutes, it reacts with oxygen and becomes reddish/brown. An IRP solves this problem at the source, before the water goes to your overhead tank, taps, or production line.

(High iron mainly causes color, taste, stains, and scaling problems; it is widely treated for acceptability and system protection.)

What an Iron Removal Plant Removes

An IRP removes contaminants that your groundwater carries in dissolved or oxidized form, depending on your water chemistry and the selected filter media. The main target is iron, and in many cases the same process can also handle manganese with the right oxidation and filtration design. For other issues like arsenic, you may need a separate treatment stage designed for that risk.

Iron (Fe) in Groundwater

An IRP removes iron (Fe) that causes yellow, red, or brown color, rust stains on toilets and tiles, metallic taste, sediment in buckets and tanks, and scaling inside pipes. When iron is controlled properly, you get clearer water and fewer plumbing problems. (Reference: WHO guidance on iron in drinking-water)

Manganese and Other Common Heavy Metals

Many tube‑wells also contain manganese (Mn), which often shows as black stains or dark deposits and can create long‑term clogging in pipelines. Manganese usually needs stronger oxidation conditions and correct media selection, so design matters more when Mn is present. (Reference: WHO guidance on manganese in drinking-water)

When Arsenic Needs a Separate Treatment Stage

If arsenic is a concern, you should not depend on an IRP alone. In some water conditions, arsenic can be reduced along with iron, but that is not a safe guarantee. For arsenic risk, you need an arsenic removal filter or a proven arsenic treatment stage, and confirm performance with testing. (Reference: WHO arsenic fact sheet)

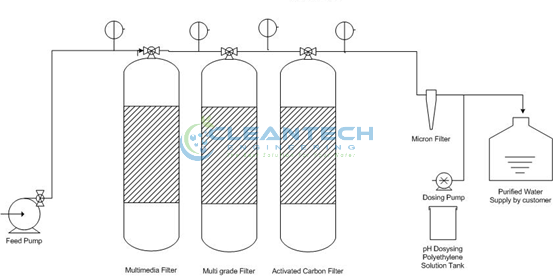

How an Iron Removal Plant Works

An iron removal plant works through a clear process: oxidation first, then filtration, then backwashing to clean the filter. Raw tube‑well water enters the system, dissolved iron is converted into particles, the filter media captures those particles, and clean water goes to your storage tank or distribution. If you need better taste or fine polishing, you can add a carbon filter or micron filtration at the end.

Oxidation Stage

Oxidation means converting dissolved iron into a form that a filter can catch. This is commonly done using aeration (air mixing, spray, or venturi), and in some cases, chemical oxidation is used when required by your iron level, manganese level, pH, or site conditions. A correct oxidation step is the main reason an IRP gives stable water instead of “red water returning” later.

Filtration Stage

Filtration is the stage where the oxidized iron particles are trapped inside the filter vessel. The filter media and the vessel size must match your flow rate and raw water quality; otherwise, the media bed will clog too fast or allow iron to pass through. This is where good design and correct loading rate matter for stable output water.

Backwashing Stage

Backwashing cleans the filter by reversing water flow through the vessel and flushing trapped iron to the drain. If backwash flow is too low, the bed will not open properly and the filter will keep clogging. If the drain line is undersized or poorly routed, backwash will fail and the system will lose performance. A stable IRP always includes backwash planning as part of the design.

Optional Polishing Stage

A polishing stage is added when you need extra clarity, less odor, or better taste. Many sites use activated carbon after IRP, and some add a micron filter for fine particles. If your goal is drinking water, you may also need UV or an RO plant, depending on your full water test and required water specification, because IRP alone is mainly for iron and related deposits.

Performance of Iron Removal Plants in Bangladesh

Many websites show “removal efficiency” percentages from field studies of community and household AIRPs. These results are helpful, but they are not a guarantee for every site.

Your actual performance depends on your raw water quality (iron, manganese, pH, turbidity, TDS), the IRP design (oxidation + contact time + vessel/media sizing), and proper backwash and servicing.

In most real-world reports, iron removal stays consistently strong when oxidation and filtration are designed correctly. Arsenic results vary widely, and usually require a separate arsenic treatment stage with lab testing to confirm performance. Check this report.

| Parameter | Reported Range (%) |

| Arsenic Removal Efficiency | 50–90 |

| Iron Removal Efficiency | 94–100 |

Seasonal Variation in Removal Efficiency

Bangladesh groundwater changes between seasons (iron/turbidity can shift), so IRP performance depends on proper backwash and maintenance. Iron removal is often stable, but arsenic removal can vary, so always design from a water test and service regularly.

Field evaluation of 20 rural AIRPs before and after monsoon:

| Season | Arsenic Removal Efficiency (%) | Iron Removal Efficiency (%) |

| Pre‑Monsoon | 67–98 | 75–93 |

| Post‑Monsoon | 74–93 | 71–92 |

Iron Removal Plant Design

Your IRP design must match your water test and your daily demand. A correct design sets the right oxidation method, contact time, vessel diameter, media depth, backwash rate, and pump selection, so your system works consistently in Bangladesh conditions.

Inputs Needed for Proper Design

To design correctly, you need capacity in LPH (for example, 500 LPH or 1000 LPH), iron ppm, manganese ppm, pH, turbidity, and TDS. These inputs decide the process, the media type, and the size of the filter vessel. If you suspect arsenic, you should test for it separately because it changes the treatment plan.

Contact Tank and Oxidation Design

A contact tank gives time for oxidation to complete before filtration. If contact time is short, iron may not fully convert and it can pass through the filter and appear later in the water tank. We design aeration and contact volume based on your flow rate, iron load, manganese presence, and available space and power.

Filter Vessel Sizing and Media Depth

The filter vessel size and media depth decide how well filtration systems perform under continuous use. Many systems use an FRP vessel for suitable capacities, while larger industrial projects may require different vessel construction based on pressure and duty. Correct media depth also helps prevent channeling and improves clarity.

Backwash Flow Rate and Drain Line Planning

Backwash design is not optional; it is part of the system specification. The backwash flow rate must be high enough to lift and clean the media bed, and the drain line must carry the backwash water safely without overflow. When backwash is planned properly, the plant stays reliable and the pressure drop stays under control.

Iron Remover Pump Selection

Pump selection depends on your required flow, total head, pipeline losses, and filter pressure drop. A good pump setup also includes proper protection, especially for dry run and electrical safety. Correct pump selection helps both normal service flow and stable backwash operation.

| Item | Depends on | Set/Size | If wrong |

| Water test + LPH | Fe, Mn, pH, turbidity, TDS | Process + overall size | Wrong treatment |

| Oxidation + contact tank | LPH + Fe/Mn | Contact time + tank volume | Iron passes, shows later |

| Filter vessel + media | LPH + turbidity | Vessel dia + media depth | Poor removal/channeling |

| Backwash + drain | Vessel + media | Backwash rate + drain size | Clogging/overflow |

| Pump | Flow + total head | Service & backwash pump | Low flow/weak backwash |

Types of Iron Removal Plants We Supply

CleanTech Engineering LTD supplies iron removal plants for home, building, and industrial use, based on your demand and site layout. A domestic system is sized for home use and daily water needs. An apartment system is a central IRP designed for multiple flats and overhead tank filling. A commercial system supports places like restaurants, hospitals, and schools where clean water prevents staining and protects plumbing. An industrial iron removal water treatment plant is designed for factories where iron can cause process issues and can foul downstream equipment like an RO plant.

Domestic Iron Removal Plant

A domestic IRP is built for home water purification needs, focusing on clear water for bathing, washing, and daily use. It is compact, easier to operate, and designed around your tube‑well test result.

Apartment Iron Removal Plant

An apartment IRP is designed as a central plant, usually before the overhead tank, to ensure stable water quality for many users. The sizing is based on peak demand and tank filling time, so pressure and flow stay consistent.

Commercial Iron Removal Plant

Commercial systems are designed for stable performance because they often run daily with higher usage. The system is selected so you get consistent clarity, less staining, and fewer complaints from users.

Industrial Iron Removal Water Treatment Plant

Industrial systems are designed for continuous duty, higher flow, and stronger reliability. They protect pipelines, storage tanks, and downstream units, and they often work as pre‑treatment before an RO plant where iron can cause membrane fouling.

| Type | Best for | Capacity basis | Typical placement | Main benefit |

| Domestic IRP | Single home | Daily family use + tube‑well test | Before house line / small tank | Compact, easy operation, clear water for bathing & washing |

| Apartment IRP | Multiple flats | Peak demand + overhead tank filling time | Before overhead tank (central) | Stable flow/pressure and consistent quality for all units |

| Commercial IRP | Restaurants, hospitals, schools | Daily high usage | Central supply line | Less staining, consistent clarity, fewer user complaints |

| Industrial IRP | Factories/process water | Continuous duty + high flow | Plant inlet / before RO | Protects equipment & RO from iron fouling, high reliability |

| Pump | Flow + total head | Service & backwash pump | Low flow/weak backwash |

Filter Media Used in Iron Removal Plants

Filter media is chosen based on how your water behaves during oxidation and filtration. Manganese greensand is used when stronger iron and manganese removal is needed and operating conditions support it. Birm media is common when pH and dissolved oxygen are suitable. Many designs use anthracite and silica sand layers to support filtration and improve turbidity control. Catalytic media options may be used when faster reactions or higher loading is needed, but they must match your water chemistry to stay stable.

Iron Removal Plant Price in Bangladesh

Iron removal plant price depends on your system capacity and treatment process, not only on the vessel. A small home system and a large industrial system have different vessel sizes, media volumes, automation levels, and installation scopes, so pricing must be based on a real specification.

At CleanTech Engineering LTD, our iron removal plant price starts from BDT 35,000, and the final price depends on your LPH capacity and water test report.

Installation and Commissioning

Installation is successful when the plant fits your site layout, and the water output meets your target. You need enough space for vessels and service access, stable power and earthing, and a safe drain line for backwash water. During commissioning, the plant is started, backwash is tested, and outlet water is checked for clarity and iron performance, with lab confirmation when needed.

1. Site Requirements

Your site should support vessel placement, piping routes, electrical safety, and drain capacity. The layout around the raw water tank and overhead tank should allow smooth operation and future maintenance.

2. Installation Steps

Installation normally follows a sequence of layout finalization, vessel placement, piping with bypass line, oxidation setup if required, electrical and control wiring for automatic systems, media loading, first backwash, and start‑up testing to confirm stable operation.

3. Testing After Installation

After installation, performance is verified by checking outlet clarity, checking pressure drop across the filter, confirming backwash flow and drain operation, and testing iron reduction with a lab report when required.

Operation and Maintenance

Your IRP performs best when you run it within the design flow and backwash on time. Backwash frequency depends on iron level and daily use; higher iron or higher usage means more frequent backwash. Regular checks help avoid sudden drops in water quality.

Backwash

Backwash cleans the media by reversing the flow and flushing out trapped iron. Automatic systems make it easier, but they still need proper pressure and a safe drain line. Skipping backwash or using weak backwash causes clogging, high pressure drop, and iron return.

Media Service

Media life varies by site. It depends on iron, manganese, turbidity, and backwash quality. A planned service schedule keeps performance stable and reduces emergency repairs.

Common Problems

- Low pressure: clogged media, weak backwash, blocked strainer, or pump issues

- Red water returning: poor oxidation/contact time, media channeling, or flow higher than design

- Bad odor: may improve with aeration or carbon; the final solution depends on the water test

- High turbidity: raw water changes or disturbed media layers

Frequently Asked Questions

Does an IRP remove arsenic?

An IRP should not be treated as a guaranteed arsenic solution. If arsenic is present, you need a proven arsenic treatment stage and confirmation through testing. (Reference: WHO arsenic fact sheet)

Will it remove the bad smell?

It can reduce smell if the smell is related to iron, manganese, or poor aeration, and many systems improve odor with good aeration and optional carbon filtration. If the smell comes from other causes, the correct treatment depends on the lab report.

How much capacity do I need?

Capacity is chosen from your daily demand, peak use, and how fast you want to fill your water tank. Many sites use designs like 500 LPH or 1000 LPH, while apartments and industrial sites may require much higher flows.

Manual vs automatic: what should I choose?

Manual systems cost less but need regular operator attention for backwashing. Automatic systems make backwash consistent and are better when you want stable performance with less daily effort, as long as the site has proper drain and pressure conditions.

How often do I need backwash?

Backwash frequency depends on iron load and usage hours. After commissioning, you should follow the backwash schedule that matches your water condition and keeps the pressure drop under control.

Can it work with overhead tanks?

Yes, many IRP installations in Bangladesh work before overhead tanks. The key is a correct pump head, piping layout, and drain routing, so both service flow and backwash work properly.

Industrial Water Plant

Industrial Water Plant