Hollow Fiber Ultrafiltration Membrane Modules

Water resources continue to be one of the top environmental concerns around the world, leading to increased water recycling efforts in water and wastewater treatment facilities globally and reducing the consumption of fresh water. Getting wastewater to an acceptable level of purification for water reuse can be challenging as it requires several steps. On the other hand, it is important to have access to pure drinking water free from suspended solids and harmful pathogens. Ultrafiltration (UF) has shown demonstrated success in both applications.

UF is a process using a physical barrier to separate water and suspended solids, turbidity, silt, bacteria, and viruses from the feed water. In a system using pressurized PureULTRA II hollow fiber modules, the feed water may come from different sources such as surface water, groundwater, secondary or tertiary treated industrial wastewater, or other sources like tertiary treated municipal wastewater.

PureULTRA II UF modules are constructed using highly hydrophilic modified PVDF hollow fiber membrane with a tight nominal pore size of 0.025 micron. The outside-in flow configuration contributes to easier cleaning as it keeps the solids, pathogens, and other foulants on the outside of the fibers. The fiber is designed to handle most feed water sources and tolerate solids loadings while operating within an optimal flux range. These fibers offer 30% higher fiber tensile strength and elongation compared to state-of-the-art fibers on the market. They reject particulate matter, Giardia cysts, and Cryptosporidium oocysts, and can help in virus removal.

Application

- RO pretreatment

- Surface water treatment (plant influent)

- Water reuse

- Tertiary wastewater treatment

- Seawater treatment

Advantages

- Deliver high flow rates

- Sustainable and supper performance

- Most effective and reliable process

- Most effective for removing particles and bacteria

- Easy to use as pre-treatment (100 μm)

- Compact and easy to installation

- High productivity

- Flexible flushing modes

- Require low chemical demand

PUREULTRA II HOLLOW FIBER UF MODULES

| Parameter | PHF-60-V | PHF-80-V | PHF-107-V |

|---|---|---|---|

| Membrane Type | Hollow Fiber | Hollow Fiber | Hollow Fiber |

| Membrane Area (m²) | 60 | 80 | 107 |

| Pore Size (μm) | 0.025 | 0.025 | 0.025 |

| Housing Material | uPVC | uPVC | uPVC |

| Potting | Epoxy / PU | Epoxy / PU | Epoxy / PU |

| Filtrate Flow Range (m3/h) | 2.4 – 7.0 | 2.4 – 9.6 | 2.4 – 12.8 |

| Filtration Flow Type | Out / In | Out / In | Out / In |

| Type of Filtration | Dead-End / Crossflow | Dead-End / Crossflow | Dead-End / Crossflow |

| Regeneration | Backflush, Forward Flush, Air Scouring | Backflush, Forward Flush, Air Scouring | Backflush, Forward Flush, Air Scouring |

| Max Feed Pressure at 20o C (bar) | 6.4 | 6.4 | 6.4 |

| pH Range | 1-12 (Operation) 1-13 (Cleaning) |

1-12 (Operation) 1-13 (Cleaning) |

1-12 (Operation) 1-13 (Cleaning) |

| Max Feed TSS (mg/l) | ≤ 350 | ≤ 350 | ≤ 350 |

Module Operating Process

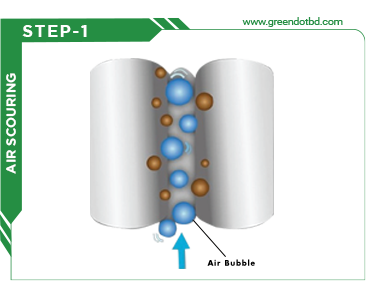

Air Sourcing

Air Sourcing

Air is injected into the module to loosen suspended solids on the fiber surface. This enables suspended solids in the module to be flushed out effectively and prevents the build-up of solids

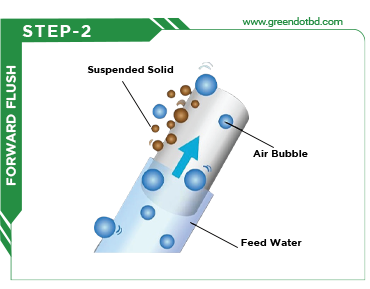

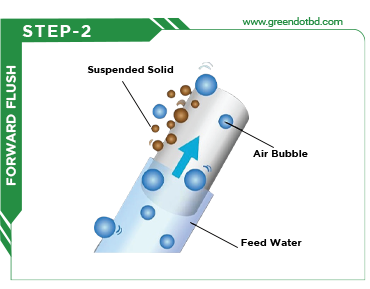

Forward Flush

Forward Flush

Feed water flushes the exterior surface of the fiber and dilutes the retentate. Air scouring is incorporated in this process to ensure the suspended solids are dislodged before the backflush. This step reduces the use of permeate during backflush.

Backflush

Backflush

The membrane module undergoes a backflush cleaning sequence where filtrate is used to backflush the membrane from the inside pf the hollow fivers, dislodging the solids attached to the surface of the fiber on the side.

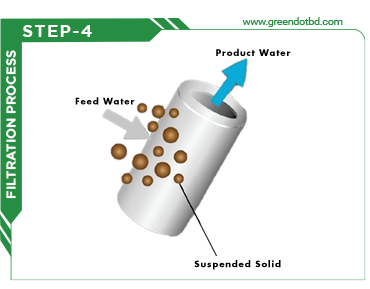

Filtration Process

Filtration Process

During the standard filtration process, the feed water contacts the exterior of the fibers and the product water is drown from the inside of the hollow fiber. This outside-in configuration has the advantage of larger membrane surface area, translating to higher flows.

Flushing Modes

| Module | Fiber Arrangement | Membrane Material | Module Diameter (mm) | Module Length (mm) |

|---|---|---|---|---|

| UA420-BT | U-Shape | PAN | 160 | 604 |

| UA860 | U-Shape | PAN | 216 | 1642 |

| UA1060HP | U-Shape | PAN | 267 | 1737 |

Oily Water & Wastewater Treatment

Stormwater Treatment

Mine Tailing Pond Treatment

RO Pretreatment

Ground Water Treatment

ADVANTAGES

- Under the proper conditions, no chemicals to purchase for maintenance. Regenerant not required.

- Iron removal efficiency is extremely high.

- Negligible labor cost: only periodic backwashing required.

- Durable material with a long life and wide temperature range.

- Weighs only 36-38 lbs./cu. ft.

PHYSICAL PROPERTIES

- Color: Black

- Bulk Density: 36-38 lbs./cu. ft.

- Mesh Size: 12 x 50

- Specific Gravity: 2.0 gm/cc

- Effective Size: 0.48 mm

- Uniformity Coefficient: 2.7

CONDITIONS FOR OPERATION

- Alkalinity should be greater than two times the combined sulfate and chloride concentration.

- Temperature Range: 35-100oF

- Water pH range: 6.8-9.0

- Dissolved Oxygen (D.O.) content must be equal to at least 15% of the iron and 29% of the manganese content.

- Bed depth: 30-36 in.

- Maximum Pressure Drop: 2-4 psi (14 -28 kPa) (Δ p increase from clean bed)

- Freeboard: 50% of bed depth (min.)

- Backwash rate: 10-12 gpm/sq. ft.

- Rinse Rate: At service flow rate

- Backwash Bed Expansion: 20-40% of bed depth (min.)

- Service flow rate: 3.5-5 gpm/sq. ft. intermittent flow rates and/or favorable local conditions may allow higher flow rates

INFLUENT AND BACKWASH LIMITATIONS

- Free chlorine concentration less than 0.5 ppm

- Hydrogen Sulfide should be removed prior to contact with Birm media

- Oil: None Present

- Polyphosphates: None present

- Organic Matter: Less than 5 ppm TOC

Related Products

Nanofiltration Elements

Nano Filter is a filtration process like other which is main used treatment for drinking water process, like water softe…

Brackish Water RO Membrane

Brackish Water RO Membrane is mostly suitable for higher TDS Water. Brack water or Brackish water, we can defined as wat…

Industrial Water Plant

Industrial Water Plant